Chocolate making is a mix of tradition, science and craft. Let’s talk a little bit about the science of chocolate and in particular, the chemistry of chocolate. It turns out that chocolate is a complex substance that can exist in multiple, different forms, called polymorphs. These are various crystalline structures that chocolate can have, each with its own special qualities. Knowing about the different types of chocolate polymorphs is important for chocolate makers and chocolate lovers, as it can affect the mouthfeel, taste, and the overall quality of the chocolate. In this blog post, we’ll delve into the science and chemistry behind these six chocolate polymorphs and why they are significant in the world of chocolate.

Introduction to chocolate polymorphs

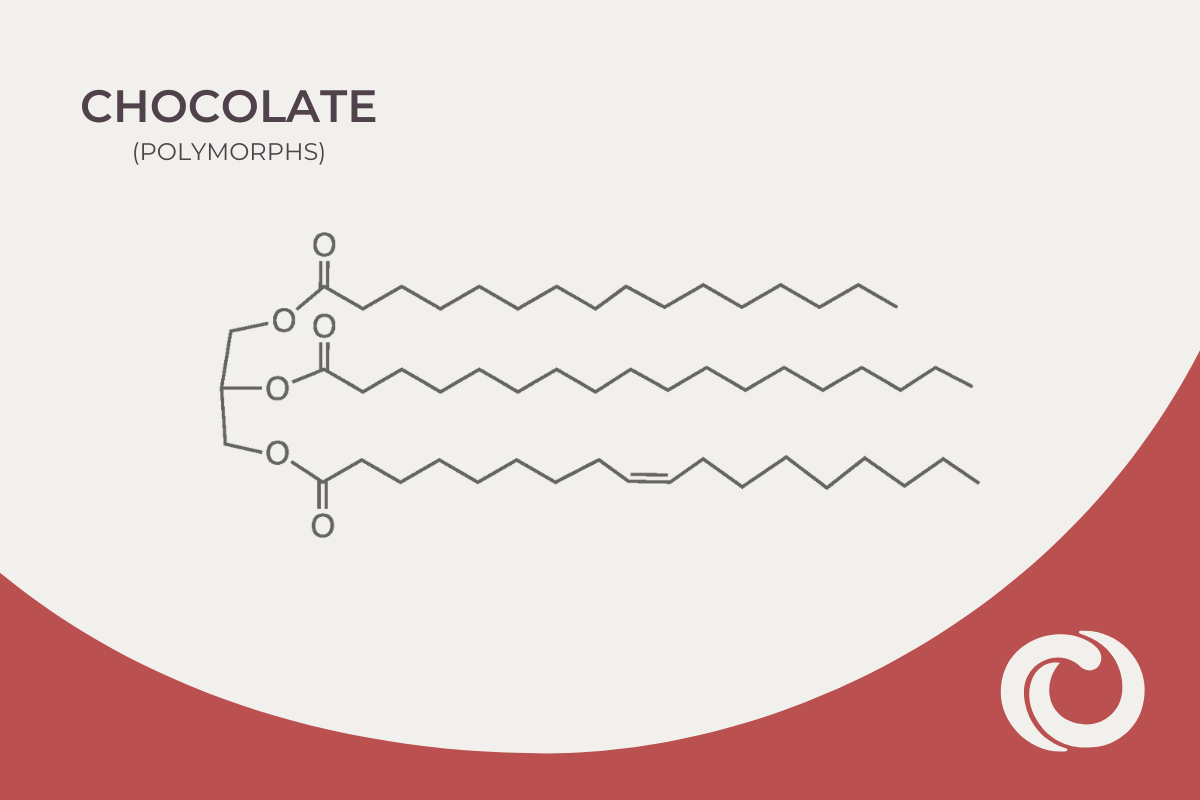

You may recall that chocolate is composed of particles (of cocoa bean, sugar, etc.) suspended in fat (cocoa butter). It turns out that cocoa butter is an unusual fat in that the molecules can connect to themselves in multiple different orientations, called polymorphs. Chocolate polymorphs are the different crystalline structures that chocolate can take on, and each of these polymorphs has its own unique properties and characteristics. Whenever chocolate goes from a liquid to a solid, it can crystallize in a variety of polymorphs.

In chocolate making, controlling the formation and type of polymorphs generated during the tempering process is critical, and involves heating and cooling the chocolate to specific temperatures to achieve the desired texture and appearance. The type of polymorphs that exist in a solid bar of chocolate can be impacted by factors such as the ingredients added to the recipe. The most common polymorphs of chocolate are known as Form IV, Form V, and Form VI, each with their own specific melting and solidification temperatures. However, Form V is the polymorph desired by chocolate makers, so how to get this less common form? Since the type of polymorphs present in solid chocolate can greatly impact its texture, flavor, and overall quality, this is a critical aspect of chocolate making.

The six types of chocolate polymorphs

There are six types of crystals, each identified by a specific name: γ (gamma), α (alpha), β’’ (beta 2), β’ (beta prime), β (beta), and super-β (super-beta). These crystals vary in the strength of the bonds between their molecules. The stronger the bonds, the more stable the form and the more energy (higher temperature) is required to break the bonds (which we describe as “melting”).

Tempering is a process of precrystallization, where we promote formation of Form V cocoa butter crystals while intentionally eliminating other forms by holding the chocolate at a higher temperature where the weaker forms can’t form. As chocolate begins to crystallize, these stable beta crystals align themselves in the proper lattice structure. Only a small percentage of these crystals is needed to seed the entire batch of chocolate — typically between 1-2% of the total chocolate volume. When enough Form V crystals are present, they serve as a template for other crystals to align correctly. When tempering is executed correctly, the process results in chocolate that is firm, smooth, shiny, crisp when broken, and resistant to melting in your hands.

Form I

Gamma Crystals (γ) – Form I melts at temperatures ranging from 60.8-64.4°F. While it’s not a critical crystal, it does occur naturally. It exhibits a soft, crumbly texture with no snap, typically formed when chocolate cools rapidly (through shock tempering in the freezer). This crystal type melts on touch and may show significant bloom.

Form II

Alpha Crystals (α) – Form II crystals melt at a temperature of about 73°F. Form II crystals are formed when chocolate cools rapidly, transitioning from Form I crystals to Form II after a brief period of freezing. These crystals melt on touch and may exhibit some bloom. The chocolate has a soft, crumbly texture with no snap.

Form III

Beta 2 Crystals (β’’) – Form III crystals melt at a temperature of about 77°F. They are formed when chocolate cools rapidly at temperatures around 41-50°F. These crystals transition from Form II to generate Form III crystals after storage at low temperatures above freezing. They melt on touch and may exhibit some bloom. The chocolate is firm with no snap.

Form IV

Beta Prime Crystals ( β’) – Form IV crystals melt at a temperature of about 80°F. They are formed by allowing melted chocolate to cool at room temperature without further tempering. These crystals transition from Form III to Form IV after storage at room temperature. They melt in the mouth and may exhibit bloom. The chocolate is firm with a good snap.

Form V

Beta Crystals (β) – Of all six crystal forms, this one stands out as the ideal choice for chocolate. These Form V crystals are exceptionally stable, forming the perfect crystal lattice. Achieved through tempering chocolate at room temperature, they represent the pinnacle of quality. Beta crystals melt at a temperature of about 93°F. Beta crystals melt smoothly in the mouth. They provide a smooth texture and a satisfying snap without any bloom, showcasing a glossy surface.

Form VI

Super Beta Crystals (super β) – Form VI crystals melt at a temperature of about 96°F. Interestingly, they cannot be generated directly from melted chocolate; instead, they form after tempered chocolate has been at room temperature for at least 16 weeks. These crystals are challenging to melt and exhibit a chalky appearance with some bloom.

Crystallization Process and Nucleation

The chocolate crystallization process starts with cocoa butter changing from liquid to solid, forming crystals. Nucleation is the first step, where tiny crystal “seeds” form in the molten chocolate, acting as the base for more crystal growth. This happens as melted chocolate cools, letting cocoa butter molecules arrange and solidify into structured forms. By carefully controlling the temperature of the molten chocolate, it is possible to control the crystal structure of the seeds that form, since each different polymorph has a different melting (and forming) temperature. Chocolate tempering is the process of generating Form V seed crystals in the molten chocolate.

Nucleation happens in two ways: primary and secondary. Primary nucleation creates crystal nuclei from the start, while secondary nucleation occurs when new crystals grow on existing crystal surfaces.

After nucleation, crystals keep growing and reproducing, forming a network throughout the chocolate. The size, shape, and how they’re arranged affect the chocolate’s texture, snap, and quality. It’s crucial to control nucleation and crystallization to generate Form V crystals so that the chocolate has the right texture and mouthfeel (this is the process of “tempering”). If the crystallization isn’t controlled , then the resulting chocolate will be a mix of different polymorphs (resulting in “untempered” chocolate). And when some of the cocoa butter molecules don’t fit nicely into the crystal network, they get squeezed to the surface of the chocolate in the form of a white powder that we call “bloom.” People often mistake untempered chocolate for moldy chocolate, but there is no reason to throw away untempered chocolate since it can always be retempered.

Applications and Implications in the chocolate industry

The crystallization process and nucleation are vital in the chocolate industry, affecting production, quality, and consumer satisfaction. They determine the texture and mouthfeel of chocolate products. The size, shape, and arrangement of cocoa butter crystals impact the shine, creaminess, and snap of chocolate, highlighting the importance of controlling crystallization and nucleation for desired outcomes.

The way chocolate crystallizes also influences how long it stays fresh and stable. When chocolate crystallizes correctly, it’s less likely to develop fat bloom (where cocoa butter moves to the surface) or sugar bloom (where sugar crystals form on the surface). These bloom issues can make chocolate look and feel less appealing.

Crystallization and nucleation also affect how flavors are released and perceived in chocolate. The crystal structure influences the trapping and release of flavor compounds during consumption, shaping the chocolate’s taste and overall sensory experience. Managing crystallization improves manufacturing efficiency by adjusting factors like temperature and cooling rates. This ensures consistent product quality and reduces waste. Monitoring and controlling these processes are vital for maintaining product consistency. Quality control measures include analyzing crystal structure, texture, and sensory evaluation to meet desired standards.

Understanding crystallization and nucleation in chocolate production enables chocolate makers to refine processes, create innovative products, and provide consumers with top-quality chocolate.

If you wanna keep learning about crystals make sure to check out this article What is chocolate tempering and what are cocoa butter crystals?

For more great articles and recipes, check out the rest of our CocoTerra blog.

If you have any questions or comments, feel free to contact us through our social media channels. We are @cocoterra_co on Instagram and Pinterest and @cocoterraco on X (aka Twitter) and Facebook.