Have you ever wondered how they measure chocolate texture? One excellent tool for this task is called a grind gauge or grindometer, also known as a Hegman gauge. It’s a steel plate with a precisely etched surface. Chocolate samples are spread over the plate to analyze the size of the chocolate particles.

Keep reading to learn all about this invaluable tool.

What’s a grind gauge?

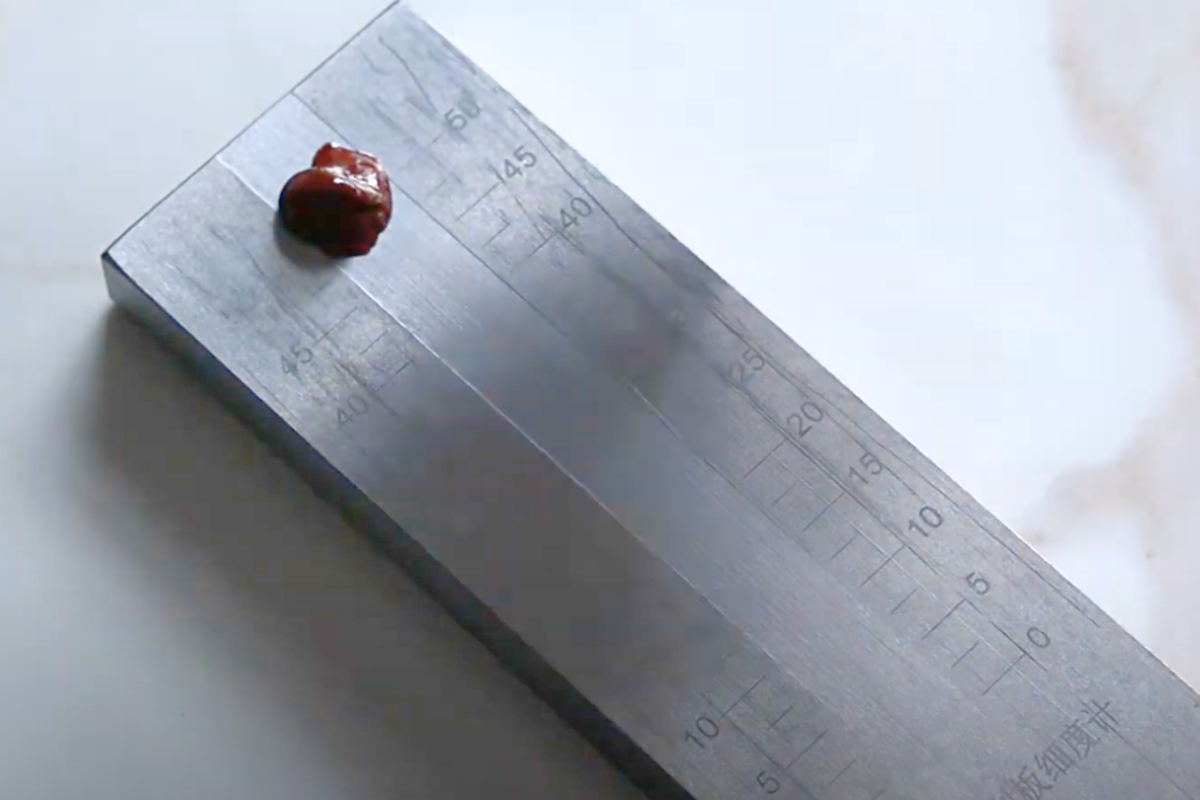

A grind gauge, also known as a Hegman gauge, is a precision instrument used to measure the particle size of materials, including chocolate. It consists of a steel plate etched with a series of channels or grooves of decreasing size. The numbers along either side of the gauge indicate the particle size measured in microns (thousandths of a millimeter).

Purpose of the grind gauge in chocolate making

One of the variables that a chocolate maker has in crafting their chocolate is deciding on the desired texture. The chocolate texture is influenced by the cocoa butter content as well as the fineness of the ingredients that make up the chocolate. In the process of making chocolate, the chocolate is processed to a particular target fineness, often referred to as particle size. It turns out that our tongues cannot easily detect individual particles below a certain threshold, so most chocolate makers will process their ingredients until they are 20 microns or smaller. So, how do you measure particle size? A grindometer, of course!

When testing the particle size of chocolate, a small sample of the liquid chocolate is spread over the gauge plate, using a standardized wiper blade to draw it across the metal plate. As the chocolate is spread across the surface, all the little particles that make up the chocolate will fall into the groves of the gauge. As the grooves get smaller and smaller, fewer particles will be able to “fit” into the grooves until the grooves are so small that none of the particles will fit and the chocolate simply slides over the surface. A finer particle size results in a longer band of the grooves being filled, while a coarser particle size leaves a shorter band with fewer grooves filled. The numerical value corresponding to the end of the band is the measured particle size. This measurement helps chocolate makers assess the texture and consistency of their product, ensuring it meets their desired specification.

How to use a grind gauge to measure particle size?

This tool is quite simple — it’s essentially a plate with lots of tiny grooves of decreasing width arranged from top to bottom, or from larger to smaller. Again, the numbers on the side represent the micron size, with 50 at the top indicating larger particle size, and smaller numbers as you go down, indicating narrower grooves and finer, smoother chocolate.

To test the chocolate, a small sample of melted chocolate is placed at the top of the gauge. A metal wiper is used to push the chocolate down along the entire length of the gauge using a constant force. To read the gauge, determine the location where the chocolate no longer covers the grooves of the gauge, transitioning from chocolate brown color to silver. Read the corresponding numerical value at this transition (it usually isn’t a sharp line but rather a slow fade). This number indicates the particle size of the smallest particles in the chocolate. It’s not always perfect since chocolate has a distribution of different particle sizes, but when it stops filling, that’s roughly the size of the smallest particle in the chocolate.

Again, since people generally can’t distinguish texture below 20 microns, the goal is to process the chocolate to approximately 20 microns for the best taste experience, which aligns with most people’s preferences.

For more great articles and recipes, check out the rest of our CocoTerra blog.

If you have any questions or comments, feel free to contact us through our social media channels. We are @cocoterra_co on Instagram and Pinterest and @cocoterraco on X (aka Twitter) and Facebook.